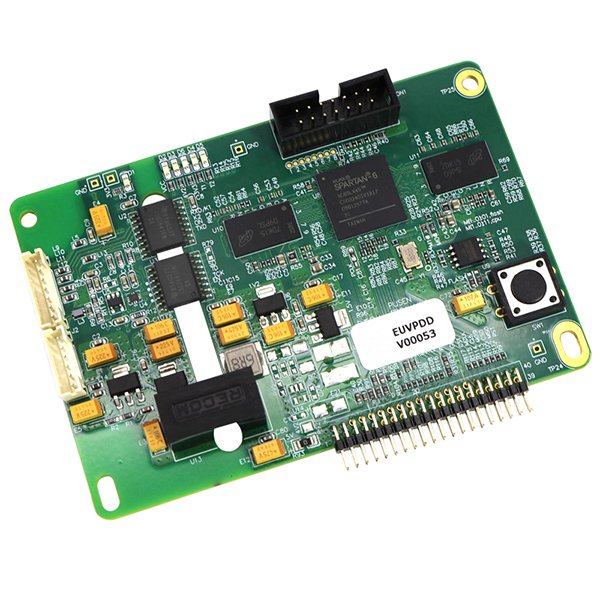

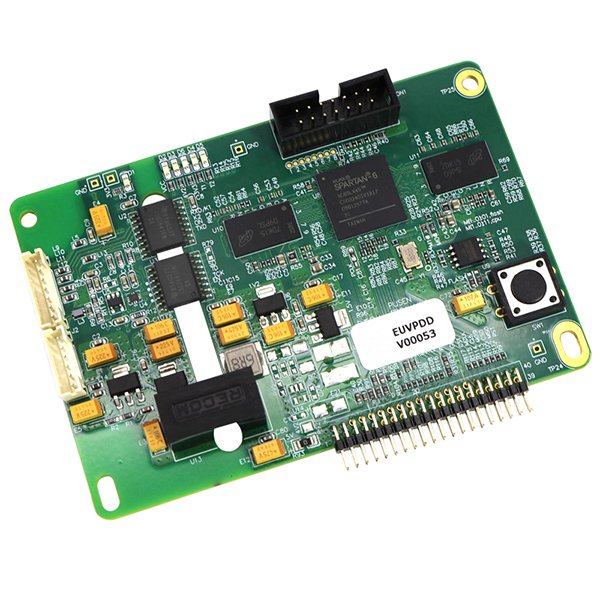

Ukuhlolwa kwekhwalithi / Ukuhlolwa

Ukuhlolwa kwe-PCB kwenza izivivinyo ezahlukahlukene emabhodini okuphrinta ukuqinisekisa ikhwalithi nokusebenza kwazo noma yiziphi izici noma izingqinamba ezingenzeka ngesikhathi sokukhiqiza, ngenkathi zithuthukisa izindleko eziphelele kanye nokunciphisa izindleko. Izindleko zokugcina.

Singanikeza ngezinsizakalo ezahlukahlukene zokuhlola i-PCB, kufaka phakathi:

Ukuhlolwa kwesandla / okubukwayo:Sithole abahloli be-PCB abafaka ukuhlolwa okubonakalayo okubhaliwe ekuhlolweni okuningi ukuze baqinisekise ukuhlolwa okuphelele kwama-PCB kanye nezinto zabo, kuqinisekisa ikhwalithi yomkhiqizo.

Ukuhlolwa kwesandla / okubukwayo:Sithole abahloli be-PCB abafaka ukuhlolwa okubonakalayo okubhaliwe ekuhlolweni okuningi ukuze baqinisekise ukuhlolwa okuphelele kwama-PCB kanye nezinto zabo, kuqinisekisa ikhwalithi yomkhiqizo.

Ukuhlolwa kwesigaxa se-microscopic:Ukuhlolwa kwesilayi kwe-PCB kufaka phakathi ukusika iBhodi Yesekethe ezingxenyeni ezincanyana zokubukwa nokuhlaziywa, ukuze zikhombe izinkinga ezingaba khona kanye neziphene.

Ukuhlolwa kwesigaxa se-microscopic:Ukuhlolwa kwesilayi kwe-PCB kufaka phakathi ukusika iBhodi Yesekethe ezingxenyeni ezincanyana zokubukwa nokuhlaziywa, ukuze zikhombe izinkinga ezingaba khona kanye neziphene.

Ukuhlolwa kwesilayi kuvame ukwenziwa ezigabeni zokuqala zokukhiqiza amabhodi okuqinisekisa ukutholwa ngesikhathi kanye nokulungiswa kwezinkinga ngesikhathi sokwakhiwa nenqubo yokukhiqiza. Le ndlela ingabheka ukushibilika, ukuxhumana kwe-interlayer, ukunemba kukagesi, nezinye izingqinamba. Lapho uqhuba izivivinyo ze-biopsy, i-microscope noma ukuskena ama-imeyili kagesi kuvame ukusetshenziselwa ukubuka nokuhlaziya izingcezu.

Ukuhlolwa kukagesi kwe-PCB:Ukuhlolwa kukagesi kwe-PCB kungasiza ekuqinisekiseni ukuthi ngabe amapharamitha kagesi nokusebenza kweBhodi Yesekethe kuhlangana okulindelwe, futhi angabona nezinkinga nezinkinga ezingaba khona.

Ukuhlolwa kukagesi kwe-PCB:Ukuhlolwa kukagesi kwe-PCB kungasiza ekuqinisekiseni ukuthi ngabe amapharamitha kagesi nokusebenza kweBhodi Yesekethe kuhlangana okulindelwe, futhi angabona nezinkinga nezinkinga ezingaba khona.

Ukuhlolwa kukagesi kwe-PCB kuvame ukufaka ukuhlolwa kokuxhumana, ukuhlolwa kokumelana, ukuhlolwa kwamandla, ukuhlolwa kokuphazamiseka, ukuhlolwa kobuqotho besiginali, nokuhlolwa kwamandla okusetshenziswa kwamandla.

Ukuhlolwa kukagesi kwe-PCB kungasebenzisa imishini yokuhlola ehlukene nezindlela, njengokufika kokuhlolwa, ama-oscilloscopes, ama-spectrum ahlaziyi, njll. Imiphumela yokuhlola izorekhodwa embikweni wokuhlola ukuze uhlole.

Ukuhlolwa kwe-AOI:Ukuhlolwa kwe-AOI (ukuhlolwa okuzenzakalelayo okuzenzakalelayo) kuyindlela yokuthola ngokuzenzakalelayo amabhodi wesifunda aphrintiwe ngokusebenzisa izindlela ezibonakalayo. Ingasetshenziswa ukuthola ngokushesha iziphambeko nezinkinga enqubweni yokukhiqiza yamabhodi wesifunda aphrintiwe, gwema amaphutha ekukhiqizweni komkhiqizo, futhi uthuthukise ikhwalithi yamabhodi wesifunda aphrintiwe. Ikhwalithi ethembekile, yehlisa amanani okuhluleka, kanye nokwenza ngcono ukusebenza kahle kokukhiqiza kanye nesivuno somkhiqizo.

Ukuhlolwa kwe-AOI:Ukuhlolwa kwe-AOI (ukuhlolwa okuzenzakalelayo okuzenzakalelayo) kuyindlela yokuthola ngokuzenzakalelayo amabhodi wesifunda aphrintiwe ngokusebenzisa izindlela ezibonakalayo. Ingasetshenziswa ukuthola ngokushesha iziphambeko nezinkinga enqubweni yokukhiqiza yamabhodi wesifunda aphrintiwe, gwema amaphutha ekukhiqizweni komkhiqizo, futhi uthuthukise ikhwalithi yamabhodi wesifunda aphrintiwe. Ikhwalithi ethembekile, yehlisa amanani okuhluleka, kanye nokwenza ngcono ukusebenza kahle kokukhiqiza kanye nesivuno somkhiqizo.

Ekuhlolweni kwe-AOI, amadivaysi athile okutholwa afana namakhamera aphezulu, imithombo ekhanyayo, nesoftware yokucubungula isithombe isetshenziselwa ukuskena nokuthwebula izithombe ze-PCB ezenziwe, bese kuthi izithombe ezithwetshiwe ziqhathaniswa nethempulethi esethiwe. Yebo, ukubona ngokuzenzakalelayo iziphambeko nezinkinga ezingaba khona, kufaka phakathi amajoyindi athengisi, izakhi, amasekethe amafushane kanye nemibuthano evulekile, ukunemba, amaphutha angaphezulu, njll.

I-ICT:Ekuhlolweni kwesekethe kusetshenziselwa ukuhlola izingxenye ze-elekthronikhi kanye nokusebenza kokuxhumeka kwesekethe ebhodini lesekethe. Ukuhlolwa kokuhlolwa kwe-ICT kungenziwa ngezigaba ezahlukahlukene zokukhiqizwa kwe-PCB, ezinjenge-PCB ekhiqizwayo, ngaphambi noma ngemuva kokufakwa kwezakhi, ukukhomba ngokushesha futhi kulungise izinkinga ebhodini lesekethe futhi uziphathe ngendlela efike ngesikhathi.

I-ICT:Ekuhlolweni kwesekethe kusetshenziselwa ukuhlola izingxenye ze-elekthronikhi kanye nokusebenza kokuxhumeka kwesekethe ebhodini lesekethe. Ukuhlolwa kokuhlolwa kwe-ICT kungenziwa ngezigaba ezahlukahlukene zokukhiqizwa kwe-PCB, ezinjenge-PCB ekhiqizwayo, ngaphambi noma ngemuva kokufakwa kwezakhi, ukukhomba ngokushesha futhi kulungise izinkinga ebhodini lesekethe futhi uziphathe ngendlela efike ngesikhathi.

Ukuhlolwa kwe-ICT kusetshenziswa imishini yokuhlola ekhethekile nesoftware ukuze kuhlolwe ngokuzenzakalela izakhi ze-elekthronikhi nezixhumi kuma-PCB. Okokusebenza kokuhlola kuthinta amaphuzu okuhlola ebhodini lokuhlola ngokusebenzisa ama-CURCOBE ngama-CUSCES kanye nama-Clamps ukuthola izici zikagesi zezinto ze-elekthronikhi ebhodini lesekethe, ezifana nathi, njll. Kungenzeka futhi ukuvivinya ibhodi yesekethe ukuze Qinisekisa ukuthi ukuxhumana kwalo kagesi kusebenza njengoba kwenziwa.

Ukujikeleza kwenaliti endizayo:Ukuhlolwa kwe-Flying Inaliti kusebenzisa uhlelo lwe-automatic Prope System ukuvivinya ukuxhumeka kwesekethe kanye nemisebenzi kwi-PCB. Le ndlela yokuhlola ayidingi ukulungiswa okubizayo kokuhlola kanye nesikhathi sokuhlela, kepha esikhundleni salokho kusetshenziswa ama-COMS ashukumisayo ukuxhumana ne-PCB Parcer ukuvivinya ukuxhuma kwesifunda namanye amapharamitha.

Ukujikeleza kwenaliti endizayo:Ukuhlolwa kwe-Flying Inaliti kusebenzisa uhlelo lwe-automatic Prope System ukuvivinya ukuxhumeka kwesekethe kanye nemisebenzi kwi-PCB. Le ndlela yokuhlola ayidingi ukulungiswa okubizayo kokuhlola kanye nesikhathi sokuhlela, kepha esikhundleni salokho kusetshenziswa ama-COMS ashukumisayo ukuxhumana ne-PCB Parcer ukuvivinya ukuxhuma kwesifunda namanye amapharamitha.

Ukuhlolwa kwenaliti endizayo kuyindlela yokuhlola engaxhumana naye engavivinya noma iyiphi indawo yebhodi yesekethe, kufaka phakathi amabhodi amancane abuyisile. Izinzuzo zale ndlela yokuhlola ziyizindleko zokuhlola eziphansi, isikhathi esifushane sokuhlola, ukushintshwa kwezinguquko zokuklama okuguquguqukayo, nokuhlolwa okusheshayo okusheshayo.

Ukuhlolwa kwesifunda okusebenzayo:Ukuhlolwa kwesekethe okusebenzayo kuyindlela yokwenza ukuhlolwa okusebenzayo kwi-PCB ukuze uqinisekise ukuthi ukwakheka kwalo kuhlangabezana yini nezidingo. Kuyindlela ephelele yokuhlola engasetshenziswa ukuhlola ukusebenza, ikhwalithi yesiginali, ukuxhumana kwesekethe, neminye imisebenzi yama-PCB.

Ukuhlolwa kwesifunda okusebenzayo:Ukuhlolwa kwesekethe okusebenzayo kuyindlela yokwenza ukuhlolwa okusebenzayo kwi-PCB ukuze uqinisekise ukuthi ukwakheka kwalo kuhlangabezana yini nezidingo. Kuyindlela ephelele yokuhlola engasetshenziswa ukuhlola ukusebenza, ikhwalithi yesiginali, ukuxhumana kwesekethe, neminye imisebenzi yama-PCB.

Ukuhlolwa kwesekethe okusebenzayo kuvame ukwenziwa ngemuva kokuthi i-PCB Wiring isiqediwe, isebenzisa ukulungiswa kokuhlola nezinhlelo zokuhlola ukulingisa izimo zangempela ze-PCB futhi zivivinye impendulo yazo ngaphansi kwezindlela ezihlukile zokusebenza. Uhlelo lokuhlola lungasetshenziswa ngohlelo lwesoftware, olungavivinya imisebenzi ehlukahlukene ye-PCB, kufaka phakathi okokufaka / okuphumayo, isikhathi, amavoluti okunikeza amandla, amapharamitha wamanje. Ngasikhathi sinye, leli khasi lingabona izingqinamba eziningi ezingaba khona nge-PCBS, ezinjengezindawo ezimfushane, ukuxhumeka okuvulekile, ukuxhumeka okungalungile, njll.

Ukuhlolwa kwesekethe okusebenzayo kuyindlela yokuhlola eyenziwe ngokwezifiso edinga uhlelo lokuhlela kanye nokuhlola ukusungulwa kwe-PCB ngayinye. Ngakho-ke, izindleko ziphakeme kakhulu, kepha zinganikeza imiphumela ephelele yokuhlola, enembile, futhi ethembekile.